SONI-FORM TECHNOLOGY

-

Uses ultrasonic energy to form hook type or mushroom type fasteners. The fastener elements are formed without the need for traditional extrusion lines and their associated complexity, safety, and environmental issues.

SINGLE LAYER

-

The fastener may be formed directly onto nonwoven materials in a single operation, eliminating the need for adhesives and making the final fastener tab very thin, soft, and pliable.

-

Fastener elements may be formed in a continuous or intermittent manner.

-

Ultrasonic technology is commonly used to bond nonwovens on disposable diaper lines, making it relatively easy to integrate this new fastener forming technology into the production environment.

-

The technology is simple, efficient and cost effective. It eliminates the need to purchase touch fasteners from outside sources and provides in-house control over the quality, performance and cost of these materials.

-

This technology has been reduced to practice and has been successfully tested using various polymer films, nonwovens and other substrates.

-OR-

ADDED MATERIAL

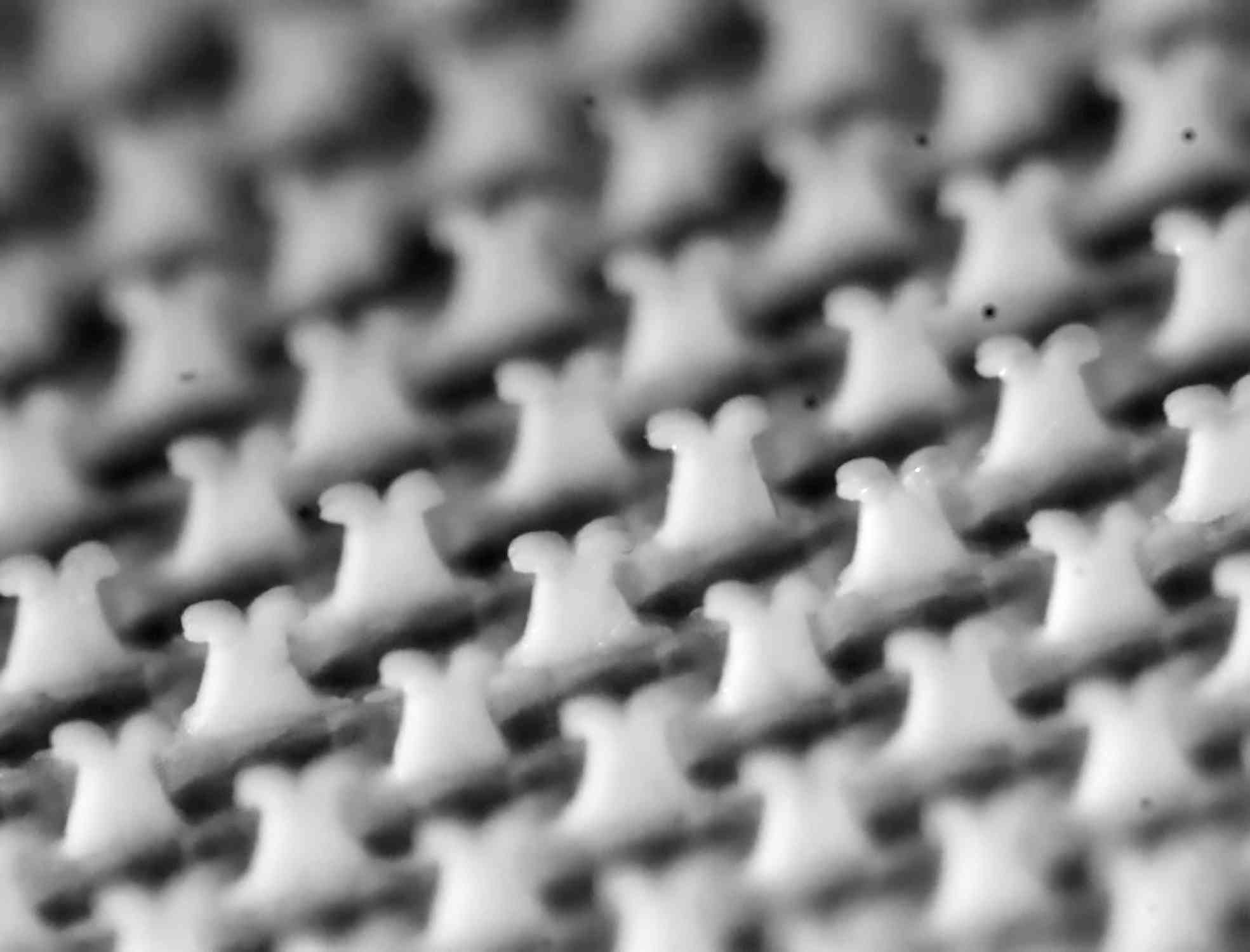

A touch fastener may be formed directly onto a nonwoven material, such as diaper side tab, by passing the nonwoven between an ultrasonic energy source and a rotating mold roll.

A portion of the nonwoven material is softened, forced into the cavities by the vibrating ultrasonic energy source and subsequently stripped off the rotating mold roll as a finished product.

The mold roll contains microscopic hook-like cavities along its outer perimeter surface.

Additional material, in the form of a nonwoven or a polymer film, may be added and passed between an ultrasonic energy source and a rotating mold roll.

A portion of the added material is softened, forced into the cavities by the vibrating ultrasonic energy source and subsequently stripped off the rotating mold roll as a finished product.

The added material becomes an integral part of the nonwoven base material.